Core Concepts and Key Technical Principles

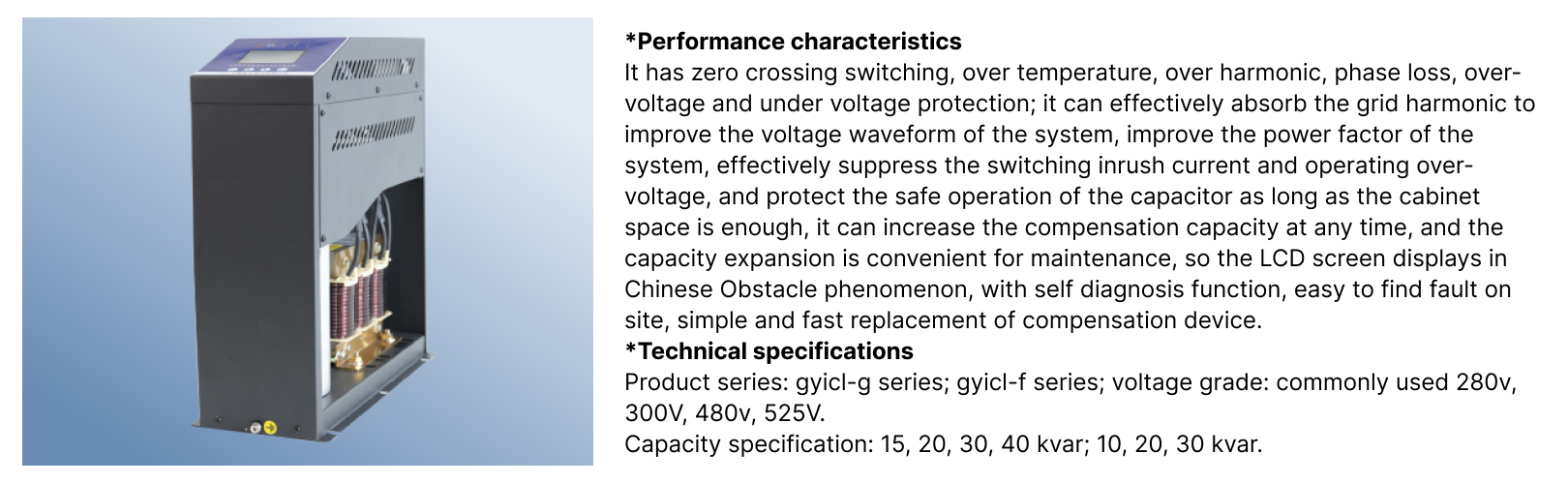

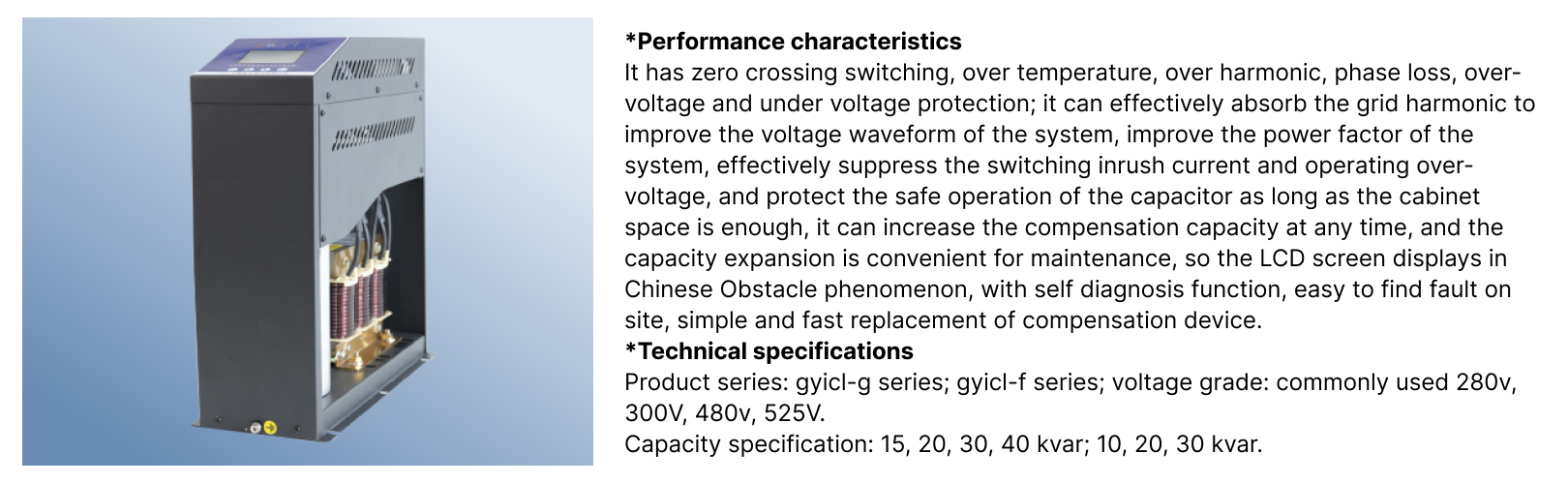

A Power Capacitor With Harmonic Suppression integrates Reactive Power Compensation with harmonic filtering mechanisms to provide a dual function in industrial power networks:

Reactive Power Compensation – The Capacitor bank stores and releases reactive energy to balance the phase difference between voltage and current, improving the power factor and reducing active power losses.

Harmonic Suppression – Harmonics generated by nonlinear loads distort the waveform of the system voltage, resulting in overheating, vibrations, and premature aging of electrical equipment. By incorporating series Reactors or passive/active filtering elements, the capacitor attenuates specific harmonic frequencies, typically between the 2nd and 50th harmonics.

Advanced models implement zero-crossing switching to minimize switching transients, overvoltage and undervoltage protection to safeguard the system under abnormal conditions, phase-loss monitoring, and overtemperature protection to prevent thermal damage. These features collectively enhance system stability and prolong the service life of the capacitor and connected equipment.

The inclusion of an LCD screen with diagnostic functionality provides on-site visibility of operational anomalies and simplifies fault identification, making maintenance faster and reducing downtime. Such monitoring allows operators to proactively respond to abnormal conditions rather than reacting after failures occur.

Product Structure, Performance, Materials, and Manufacturing

Structural Overview

Power capacitors with harmonic suppression typically consist of:

Capacitor Cells – Constructed with high-quality dielectric materials, such as metallized polypropylene film, which provide high dielectric strength and long-term reliability.

Series Reactor – A dry-type iron-core reactor placed in series with the capacitor to limit harmonic resonance and inrush currents, enhancing harmonic suppression.

Protection and Control Unit – Integrated circuits or microControllers manage the protective functions (overvoltage, undervoltage, overcurrent, overtemperature) and facilitate digital monitoring.

Cabinet Interface – Designed for easy integration into low-voltage compensation cabinets, with modular arrangements allowing flexible capacity expansion.

Performance and Technical Specifications

Voltage Ratings: 280 V, 300 V, 480 V, 525 V

Capacity Ratings: 10–40 kvar, depending on the series and application requirements

Protection Features: Zero-crossing switching, overtemperature, overvoltage, undervoltage, phase loss, and over-harmonic protection

Noise Level: Engineered to operate with minimal acoustic impact in industrial environments

Capacity Expansion: Modular design permits incremental capacity addition, enabling scalable solutions without large system redesigns

Manufacturing and Material Considerations

High-quality capacitors utilize film metallization and epoxy encapsulation, ensuring minimal leakage, mechanical robustness, and excellent thermal endurance. Series reactors are wound with high-purity silicon steel laminations to reduce eddy current losses while maximizing magnetic flux stability. Advanced assembly processes ensure precise alignment and consistent contact quality, which are critical for reliable operation under frequent switching conditions.

Key Factors Affecting Quality and Performance

The operational success of a power capacitor with harmonic suppression depends on several factors:

Voltage and Current Ratings Accuracy – Selecting capacitors that match or slightly exceed system voltage avoids overvoltage stress while optimizing reactive power correction.

Harmonic Profile Consideration – Accurate harmonic analysis of the site is necessary to determine the optimal reactor and filter design to prevent resonance and ensure effective suppression.

Thermal Management – Adequate spacing, airflow, and heat-resistant materials are necessary to prevent thermal runaway, particularly in high-density cabinets.

Switching Technology – Zero-crossing switching reduces transient spikes, prevents capacitor overvoltage, and extends component lifespan.

Maintenance Accessibility – Modular designs with diagnostic LCDs facilitate quick identification of faulty components and simple replacement, reducing operational downtime.

Supply Chain and Supplier Selection Criteria

Selecting a reliable supplier of power capacitors with harmonic suppression is critical for industrial applications:

Standards Compliance: IEC 60831 and equivalent certifications ensure the capacitor can safely operate under industrial load conditions.

Documentation and Support: Complete datasheets, wiring diagrams, and on-site installation guidance facilitate safe integration and troubleshooting.

Component Quality: Proven dielectric films, high-purity metals for reactors, and microcontroller-based protection units contribute to long-term reliability.

Engineering Expertise: Suppliers that provide harmonic analysis support, system design guidance, and after-sales service reduce operational risk.

Traceability and Certification: ISO 9001-certified manufacturers with component traceability ensure consistent quality and warranty compliance.

Common Challenges and Industry Pain Points

Harmonic Overload

Nonlinear loads can produce harmonic currents that exceed acceptable limits. Without proper suppression, this leads to voltage distortion, transformer overheating, and equipment failure.

Inrush Currents

Capacitors switched under load can draw high inrush currents. Series reactors and zero-crossing switching are essential to mitigate these transients.

Maintenance and Fault Detection

Operators face challenges in quickly identifying and replacing faulty capacitors. Integrated LCD diagnostic screens significantly simplify this task, minimizing downtime.

System Design Complexity

Correct sizing of capacitors and reactors requires detailed load analysis and harmonic evaluation to ensure both efficient compensation and resonance avoidance.

Application Scenarios and Industry Use Cases

Industrial Manufacturing Facilities

High-power motors, welding machines, and production lines create reactive loads and harmonics. Power capacitors with harmonic suppression stabilize voltage and improve power factor, reducing energy costs and equipment wear.

Renewable Energy Integration

Photovoltaic inverters and wind turbines introduce dynamic reactive power variations. SVG-integrated capacitor solutions provide fast and precise compensation, improving grid compliance.

Commercial Buildings and Data Centers

Reactive compensation and harmonic suppression reduce energy losses, prevent voltage sags, and maintain reliable operation of sensitive electronic equipment.

Distribution Substations

Capacitors with harmonic suppression improve network power quality, reduce transmission losses, and maintain voltage levels across medium- and low-voltage networks.

Current Trends and Future Directions

Digital Monitoring and Diagnostics: Enhanced LCD and networked monitoring allow predictive maintenance and remote fault detection.

Hybrid Compensation Systems: Combining capacitors with Active Power Filters and SVGs addresses both reactive power and harmonic distortion comprehensively.

Modular, Scalable Designs: Compact, stackable modules enable gradual capacity expansion without major system overhaul.

Advanced Materials: Improved dielectric films and reactor core materials enhance thermal stability, reduce losses, and increase service life.

Frequently Asked Questions (FAQ)

Q: What is the main advantage of a power capacitor with harmonic suppression?

A: It simultaneously improves power factor and mitigates harmonics, protecting equipment and enhancing voltage stability.

Q: Can these capacitors be used in high-harmonic environments?

A: Yes, series reactors and protection features are specifically designed to handle harmonics up to the 50th order.

Q: How is maintenance simplified?

A: Integrated LCD diagnostic screens allow operators to quickly identify faults and replace modules without extensive downtime.

English

English

Español

Español

Portugues

Portugues

Pусский

Pусский

Français

Français

Deutsch

Deutsch

日本語

日本語

한국어

한국어

العربية

العربية

Italiano

Italiano

Nederlands

Nederlands

Svenska

Svenska

Polski

Polski

Türk dili

Türk dili

हिन्दी

हिन्दी

Indonesia

Indonesia

Melayu

Melayu

dansk

dansk

Magyar

Magyar

қазақ

қазақ

বাংলা

বাংলা

עִברִית

עִברִית

čeština

čeština

українська

українська

беларускі

беларускі

Filipino

Filipino

Suomalainen

Suomalainen

اردو

اردو

հայերեն

հայերեն

български

български

Hrvatski

Hrvatski

galego

galego

नेपाल

नेपाल

euskara

euskara

Shqipëria

Shqipëria

Башҡорт

Башҡорт

Türkmenler

Türkmenler

Ilocano

Ilocano

Нохчийн

Нохчийн

WhatsApp

WhatsApp TELEFAONINA

TELEFAONINA